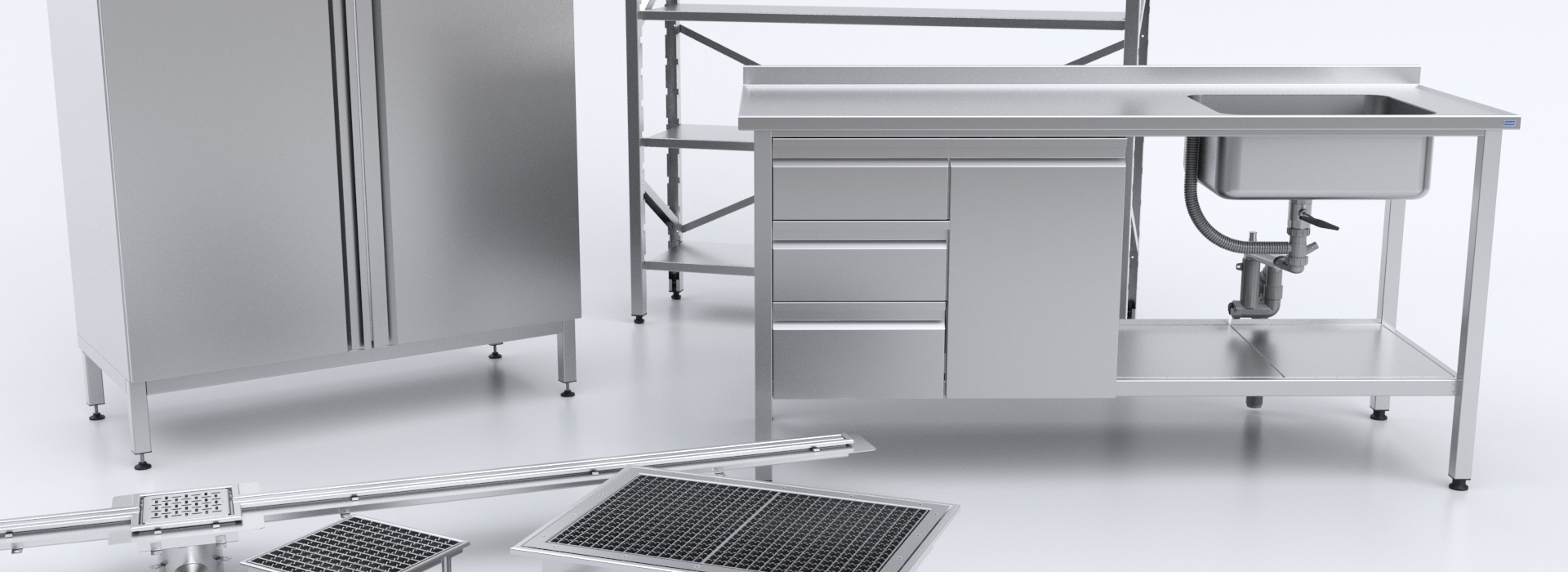

Benefits of Stainless Steel

Stainless steel is both versatile and durable, offering many advantages over other metals and materials. The steel's unique combination of functionality, wear resistance, and aesthetics makes it an excellent choice for many projects. Here are some of the key reasons why you should choose stainless steel:

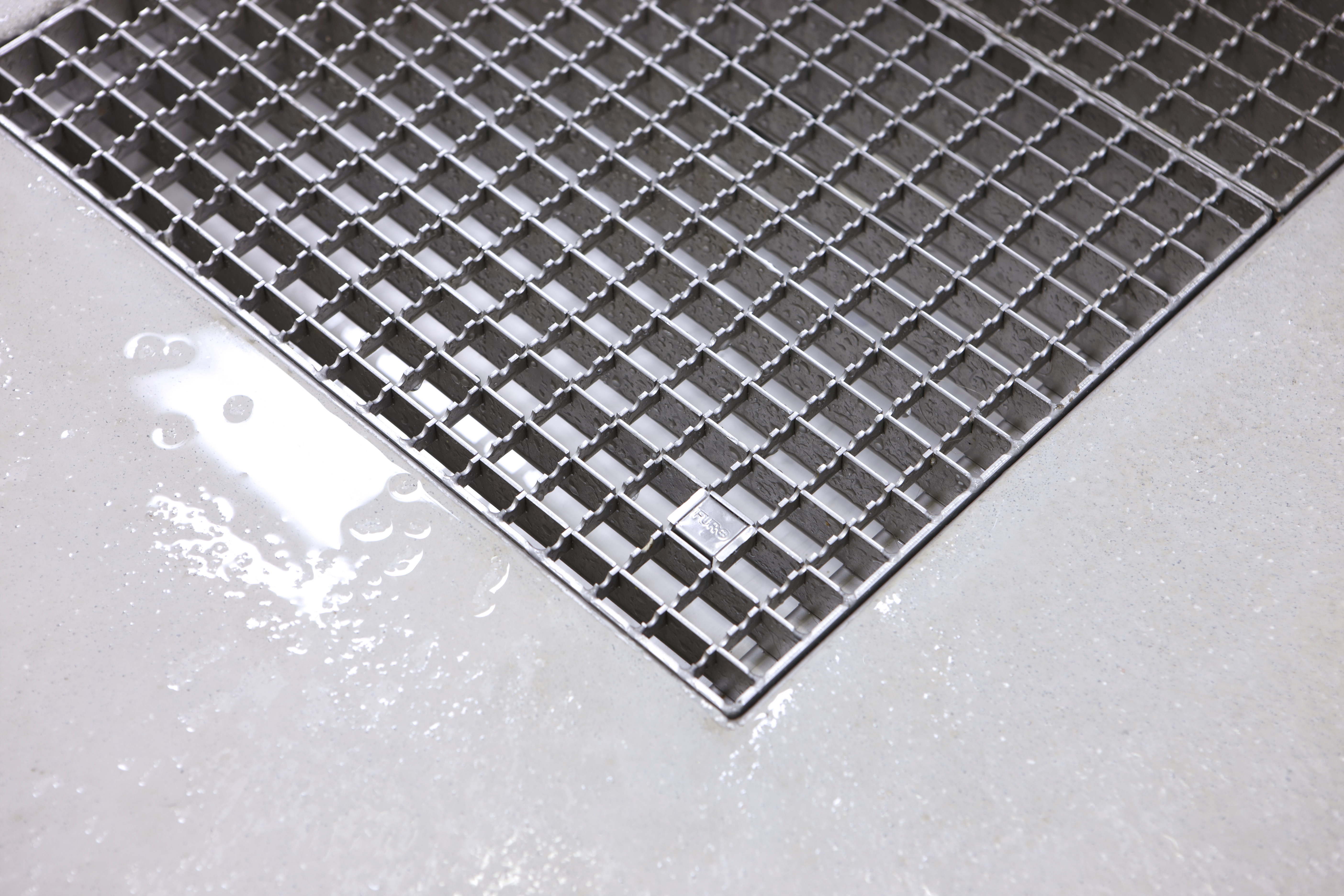

Corrosion Resistance

Stainless steel is known for its exceptional resistance to rust and corrosion. This makes it ideal for both indoor and outdoor use, even in damp or chemically aggressive environments.

Long Durability

With its superior durability and wear resistance, stainless steel offers long-term performance and a long lifespan. This reduces the need for frequent replacements and repairs, resulting in lower maintenance costs and increased cost-efficiency for our customers.

Hygienic Benefits

Stainless steel is particularly suitable for environments where hygiene is of utmost importance, such as food processing and medical applications. The smooth and non-porous surface of stainless steel makes it easy to clean and prevents bacterial growth, contributing to a cleaner and safer working environment.

Flexible and Customizable

The material is highly flexible and can be easily shaped and processed to meet specific needs and requirements. Whether it involves industrial components, construction materials, or products, stainless steel offers a high degree of adaptability and versatility.

Eco-friendly

One of the most significant advantages of stainless steel is its recyclability. The material can be endlessly recycled without compromising quality, reducing waste and conserving energy. The recycling rate is high, with around 90% of all stainless steel products being recycled when they are no longer in use. Recycling stainless steel saves nearly 80% of the energy that would otherwise be needed to produce new steel from iron ore.

By choosing products made from stainless steel, you contribute to a more sustainable and eco-friendly future.

The History of Stainless Steel

Stainless steel, as we know it today, has its origins in the early 20th century. The first groundbreaking discovery was made by the British scientist and metallurgist Harry Brearley in 1913. Brearley worked in Sheffield, England, with the goal of developing a steel alloy that would have improved wear resistance and solve problems with rust attacks in the British navy's gun barrels.

Brearley experimented with adding various metals to iron, and during his experiments, he discovered a mixture of iron and chromium that proved to be highly resistant to rust and corrosion.

How Chromium Improves Stainless Steel

Today, we know that iron alloyed with at least 12% chromium gains increased resistance to rust. This happens as chromium reacts with oxygen in the air to form a very thin, protective passive layer on the steel's surface.

The layer prevents corrosion – what we commonly refer to as rust. If the layer is damaged, a new protective layer forms when it comes into contact with oxygen.

Common alloys

At Furhoffs, we primarily work with the two most common stainless steel alloys – EN 1.4301 and EN 1.4404 (also known as "acid-resistant" stainless steel). Read more about the content and uses of these different steels:

EN 1.4301 / AISI 304

Content: Approximately 18% chromium and 8% nickel

Use: This is the most popular and versatile stainless steel alloy, often used in indoor environments and where there are not strong corrosive conditions. Common applications include kitchen equipment, furniture, and construction details.

EN 1.4404 / AISI 316L

Content: Approximately 18% chromium, 11% nickel, and 2.1% molybdenum

Use: This alloy, known as "acid-resistant steel," is ideal for environments with higher corrosion, such as coastal areas and industrial settings where chloride compounds are common. It is also used in healthcare and the food industry due to its hygienic properties.